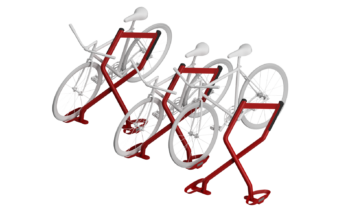

Omnium™ No Scratch® Bike Rack

NEED HELP? 888-661-0555 / M-F: 7AM - 4PM PACIFIC

Optimized BIM Files Built for Designers

Streamline your workflow with design files that ensure accuracy and compliance.

Comprehensive BIM Files Ready for Use!

Designed for efficiency and precision, these parametric families adapt instantly to design changes, saving you time and ensuring seamless APBP compliance.

Includes DWG, DXF, Revit, & SketchUp formats.

The term “Omnium” is synonymous with the best overall result in three track cycling events.

Sportworks latest horizontal rack was inspired by this concept, and designed with the following criteria:

Provide high density and orderly bicycle parking

Utilize Sportworks No Scratch bumper to prevent damage, and eliminate interference between bicycles

Optimal aesthetics and streetscape appeal

The result is the Omnium No Scratch Bicycle Rack - best in class for user experience and style.

The Omnium Features:

Staggered design minimizes bike-to-bike interference, entanglement, and allows all bikes to be parked in the same direction without creating handlebar interference

Front wheel wells provide stability and promote consistent bicycle positioning

Highly secure and U-Lock compatible

No Scratch bumper protects bicycle frames

Crossbar can be customized with your company logo or artwork

Finishes

Sportworks bike parking products are available in a wide variety of finishes and materials. Please contact us for specific details regarding minimum lot size charges on finishes.

TGIC Powder Coat

This polyester-based finish is well suited for bike racks made from mild steel, and is available in a wide variety of colors. Powder coating serves as a protective barrier to the various environment elements that cause corrosion. To further increase corrosion resistance, Sportworks recommends an additional zinc plated undercoat be applied prior to the powder coating process. Zinc acts as a sacrificial anode to protect the base metal from corrosion should the powder coat become chipped.

PPA-571 Thermoplastic Powder Coat

This thermoplastic finish is also well suited for mild steel racks, and Plascoat’s special formulation (PPA-571) produces a more flexible and robust coating. When compared to polyester-based powder coatings, PPA-571 thermoplastic powder coatings are tougher, more resistant to chips, and naturally graffiti resistant. This finish is also available in a wide variety of colors.

Galvanized

If color is not a requirement, this hot dip galvanized finish is a good choice for durability, low cost and corrosion protection on mild steel racks. While a galvanized finish will appear rough when compared to zinc plated and powder coated finishes, galvanizing provides the highest degree of corrosion resistance of all three. Additionally, galvanizing can also be used as an under coating treatment to TGIC and PPA powder coats. All Sportworks galvanized bike racks are finished to ASTM A123.

Bead Blast

Unlike powder coating and galvanizing, this finish removes material during the application process, and is ideal for stainless steel racks. Small glass particles (media) traveling at high velocities impact the metal removing the outer surface, and resulting in a mildly-textured or matted finish. Similar to galvanizing, there are no color options available for this type of finish. Sportworks stainless steel bike racks represent the highest level of corrosion protection available.

Materials

Mild Steel

The primary alloying element of mild steel is carbon. This enables bending and forming, while maintaining strong mechanical properties. A finish is required for outdoor applications (galvanizing, plating, powder coating, thermoplastics, or painting) as unfinished mild steel will rust and corrode when exposed to air and moisture.

Stainless Steel

Stainless steel does not stain, corrode, or rust as easily as mild steel because it contains more chromium and nickel. A passive film of oxides prevents surface corrosion and blocks corrosion from spreading into the internal structure of the metal. Stainless steel can still corrode and discolor in certain environments, however the strength and appearance can withstand exposure in most outdoor locations.

Powder Coat Colors

Sportworks offers the following standard color palette for our bicycle racks. All standard colors are available in both a polyester and a thermoplastic powder coat and are typically available within our standard lead time. All polyester powder coat colors include an epoxy primer undercoat. Zinc plating is also available as an alternate undercoat option.

Custom Colors

Custom colors are available, and subject to minimum orders and lot charges. Custom colors matching RAL or Pantone, as well as anti-graffiti powder coat colors are available and may involve extended lead times and/or lot changes. Plascoat thermoplastic powder coat provides the following benefits: excellent corrosion, fade, chip, abrasion and graffiti resistance. For more information regarding custom colors contact our sales team.

Mounting Options

Complete installation instructions for all Sportworks bike parking products are available as a PDF on this page or by visiting the downloads section of the website.

Surface Mount

Surface mount uses permanent or removable anchors to secure the bicycle rack mounting flange to concrete.

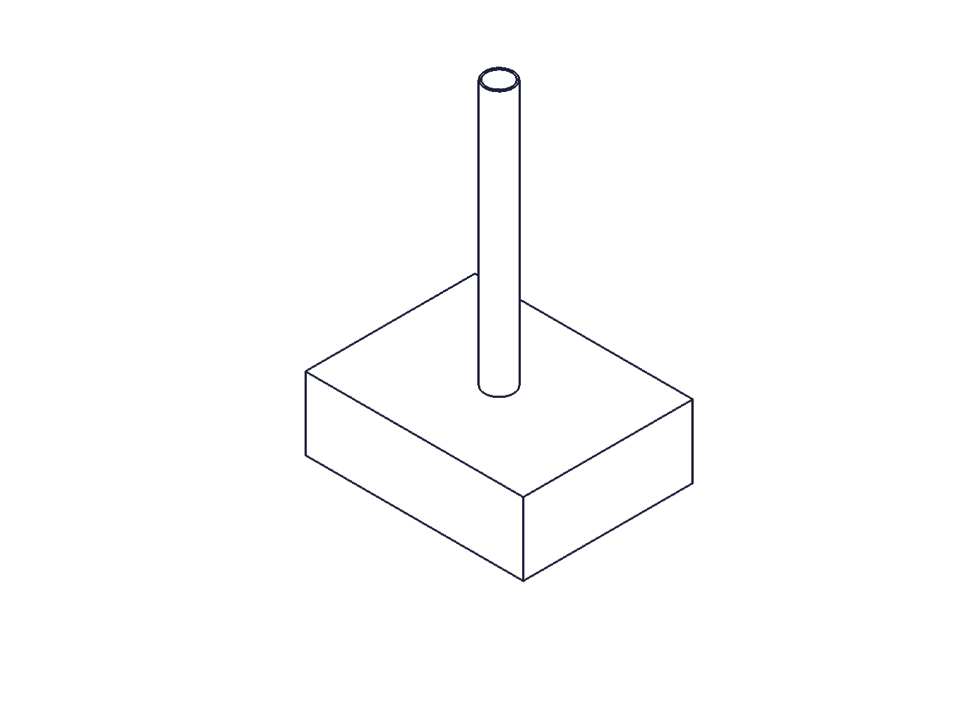

Mounting In Ground Mount

Embedding the bicycle rack into concrete represents the most secure mount for a bicycle rack. An additional 10” of length is included on the bicycle rack post(s) for casting in concrete.

Tamper Resistant Anchors

Tamper resistant anchors are recommended for surface mounted racks. When the substrate is concrete, we recommend stainless steel wedge anchors with stainless steel breakaway nuts, also known as shear nuts. These nuts make it much more difficult for someone to tamper with or remove an installed bicycle rack.

Breakaway Nut Pre Installation

The breakaway nut consists of a hex nut portion at the top and a smooth conical sleeve located just below. Install the wedge anchor using standard tools and then tighten the breakaway nut.

Breakaway Nut Installed

The hex portion of the nut will shear off when the design shear torque is exceeded. Once the hex nut shears off, only the smooth conical sleeve will remain. The tamper resistant anchor is now installed. The cone is shaped so standard tools will not be able to grip and remove the nut.

Green Certifications

At Sportworks, we take environmental responsibility very seriously. Our bike racks are made with post-industrial recycled steel. We trace the location of origin and material/chemical composition of all the raw materials and sourced components we use. We also monitor VOC content in our finishing materials, and use recycled content in our packaging materials.

Installation of Sportworks bike racks may assist your project in qualifying for the following green building certification programs:

LEED®

SS Credit 4.2-Alternative Transportation-Bicycle Storage and Changing Rooms

To qualify for this credit, commercial, institutional or residential buildings must provide secure bicycle parking within 200 yards of a building entrance.MR Credit 4.1—Recycled Content—10% | MR Credit 4.2—Recycled Content—20%

Sportworks stainless steel bicycle racks average 87% total recycled content; 72% post-consumer recycled content; 15% pre-consumer (post-industrial) recycled content.MR Credit 5.1—Regional Materials—10% Extracted, Processed & Manufactured Regionally | MR Credit 5.2—Regional Materials—20% Extracted, Processed & Manufactured Regionally

Our manufacturing facility is in Woodinville, Washington. If your project is within 500 miles of our factory, you may qualify for these credits.

Living Building Challenge

The Omnium™ No Scratch® Bike Rack is fully compliant with the Materials Red List of the Living Building Challenge, which means they don't contain harmful materials including formaldehyde, halogenated flame retardants, PVC, lead, mercury, CFC's, HCFC's, neoprene (chloroprene) and cadmium.

Our bike racks may also help fulfill the Car-Free Living, Appropriate Sourcing, Conservation & Reuse, and the Human Scale & Humane Places imperatives within Version 2.0 of the Living Building Challenge.

Green Globes™

Sportworks bike racks can help you qualify for the following Green Globes™ credits:

E.2—Minimal Consumption of Resources

Sportworks racks are made with recycled content and may be considered locally manufactured depending on the location of your project in relation to our factory in Woodinville, Washington.C.5—Energy Efficient Transportation

Sportworks racks support the requirement of providing safe storage areas with fixed mountings for bicycles.

Related Products

Tofino™ No Scratch® Bike Rack

Modern and streamlined design with a No Scratch® bumper to keep bicycles damage-free. Optimal for indoor or outdoor use. Made in the USA of 87% recycled materials.

Cane Detectable (ADA Compliant) Tofino™ No Scratch® Bike Rack

ADA-compliant version of our Tofino rack (all the same features and benefits), ideal for pedestrian areas and circulation paths.

Oahu™ No Scratch® Bike Rack

Unique circular design with a No Scratch® bumper to keep bicycles damage-free. Optimal for indoor or outdoor use. Made in the USA of 87% recycled materials.

Westport™ No Scratch® Bike Rack

Compact design for indoor or outdoor use. The No Scratch® bumper to keep bicycles damage-free. ADA-compliant and made in the USA of 87% recycled materials.

Plaza™ High Density Bike Rack

The Plaza™ bike rack is designed to provide high density, organized bike parking, all within a space efficient footprint. Supports up to 12 bikes, single and double-sided configurations are available.

Plaza Jr™ High Density Bike Rack

The Plaza Jr. bike parking rack is available as a 6-bike single sided rack or 12-bike double sided rack - the perfect bike parking solution for kid's bikes.